Nitrogen compressor is a device used to compress and deliver dry nitrogen. In addition to the main engine, the unit also includes various levels of gas coolers, inlet and outlet buffers, asynchronous motors (YKK630-12), oil supply devices, etc. The dry nitrogen enters the compressor through the filter, and reaches the specified high pressure through multi-stage compression. After each stage of compression, the hot gas is cooled by a water-cooled shell-and-tube heat exchanger.

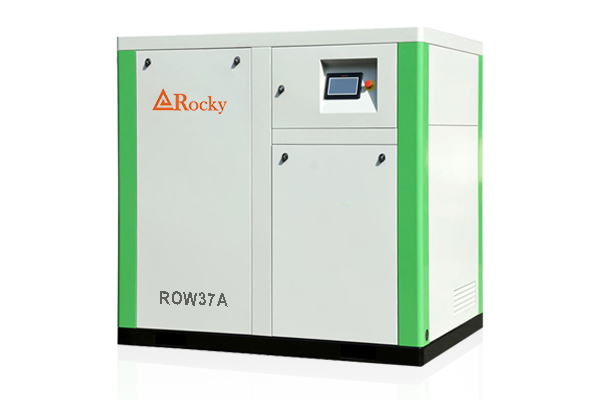

Air compressor is the basic product of industrial modernization. The often said electrical and automation have the meaning of full pneumatic knowledge; and the air compressor provides air source power and is the main body of the electromechanical bleed air source device, the core equipment of the pneumatic system. It is a device that converts the mechanical energy of the prime mover (usually an electric motor) into gas pressure energy, and is a device for generating airway pressure of compressed air. Its composition includes oil circulation system, gas circulation system, water circulation system, power distribution system, screen protection system, DC power supply system, and DTC control system.

From the perspective of installation position: the air compressor should be installed in front of the nitrogen compressor (the air compressor provides preliminary compressed air to the nitrogen compressor, and then the nitrogen compressor separates the oxygen in the air through membrane separation devices to provide high Nitrogen under pressure.