Conditions such as brand strength and maintenance can effectively increase the service life of screw air compressors. How many years is the service life of a general screw air compressor? The higher the price of air compressors, the higher the quality of the air compressors they buy. Many companies hope that the longer the air compressor will last, the better. However, the air compressors of the same brand and model, Used in the hands of different people, the working life of the screw air compressor is also different. Some can be used for 8 to 10 years without any failure, but some have only been used for one or two years, and there are serious maintenance problems. The malfunctioning one can’t be used anymore. What caused this situation?

The first factor: environmental factors, different regions and environments with large temperature differences will have a certain impact on the service life of the air compressor. The other is the surrounding environment when the air compressor is used, such as a dusty environment. It also has an impact on the life of the air compressor.

The second factor: whether the maintenance is on time, an air compressor is maintained in accordance with the regulations, then its service life must be longer than that of an air compressor that is not maintained.

The third factor: The rotation speed of the screw air compressor has an inevitable relationship with the maintenance cycle of the main engine. When the speed of the machine head is high, the wear of the bearing directly affects the service life of the bearing, and the excessively high air compressor speed can easily cause the screw The condition of the nose locked.

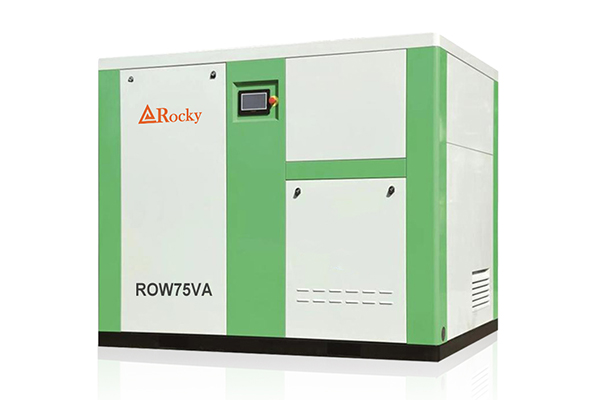

The fourth factor: the strength of the selected manufacturer. The strength of screw air compressor manufacturers is different, and the air compressors produced are definitely different. The strength of the manufacturer is proportional to the service life of the screw air compressor. The strength of the manufacturer gives the air compressor a higher technical content, so it rarely fails. Repair issues.

The fifth factor: raw materials produced. The core component of the screw air compressor is the screw rotor, and the life of the screw rotor determines the service life of the air compressor. Imported products can often be used for about 15 years, while domestically produced machines can only be used for about 5 years. This is why imported The reason why the price of the air compressor is higher than that of the domestic air compressor.

Therefore, in order to prolong the service life of the air compressor of the production enterprise, the following seven precautions must be paid attention to when the air compressor is in operation:

1. It is necessary to create a stable and efficient operating environment for the efficient and normal operation of the air compressor, then it is necessary to keep the station sanitary and clean, the air is dry, and the ventilation effect is good. Direct baking and direct sunlight cause exposure,

2. The maximum pressure is not allowed to exceed the specified maximum range value.

3. Ensure that the safety valve is sensitive and effective.

4. The gas storage tanks and gas pipelines must be tested every two years as a cycle to see if they need to be replaced normally.

5. When we start the machine, we must start carrying it under no load, and wait until everything is normal before starting to gradually enter the load operation.

6. It is forbidden to stand in front of the air compressor outlet. Before opening the air supply valve, the corresponding air pipelines should be kept intact.

7. When there is electric leakage, air leakage, oil leakage, water leakage, and the value of each parameter exceeds the specified range value, etc., the air compressor should be stopped for inspection immediately, and normal operation can be resumed after the fault is found and analyzed.

For the life of screw air compressor, the key lies in the manufacturer's strength, brand factors, maintenance, etc. of the selected equipment. Under normal circumstances, a screw air compressor with excellent quality can be used for 10 years without major problems.