The selection of air compressors has a great relationship with the industry. The first thing to consider is the production scale, the second is the capital budget, and the third is the use site, environment and other factors. Many industries operate air compressors 24 hours a day, and the energy consumption cost of these industries will be relatively high at this time, the choice of frequency conversion air compressor can effectively reduce the cost. Generally speaking, users need to choose the model of air compressor according to local conditions. Today, I will introduce to you how to choose the air compressor model suitable for you in the sandblasting machine industry.

How to choose:

1. Determination of air volume

To reasonably determine the gas consumption, it is necessary to consider the leakage of pipelines and the gas used for blowing the dryer, the gas used for the back blowing of the dust collector of the sandblasting machine and the gas consumption of other equipment. If you choose a large gas volume, it will increase the investment in equipment and electricity. If you choose a small gas volume, the gas pressure will not reach the rated pressure, and it will not be able to sandblasters and other equipment are in normal use. Generally, a 10% margin should be left.

2. Work pressure

First determine the air pressure of all equipment, select the highest air pressure of the equipment, and then choose the air compressor. If the equipment has different air pressure, then connect the highest air pressure equipment first, and then connect them in sequence, according to the pressure of each equipment. requirements, use subtraction in the connection pressure valve to meet the pressure requirements of each equipment. The higher the pressure, the greater the power consumption. If the equipment requires a large pressure difference, it is better to choose a different air compressor to use, which can reduce the cost.

3. Reasonable air compressor quality requirements

Requirements for oil content: You can choose a combination of different precision oil removal filters to meet the requirements. Requirements for water content: refrigerated dryer can be used when sandblasting machine is selected. Requirements for dust content: Different dust removal filter combinations can be selected according to the site environment to meet the requirements. enough use as the principle, do not blindly improve the quality to increase the purchase cost of equipment.

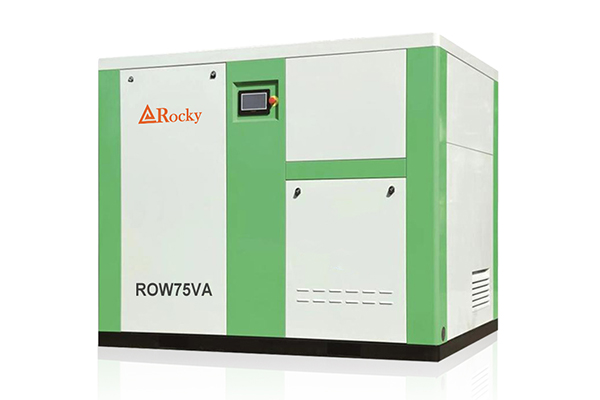

4. Air compressor model selection

The advantages of piston air compressors are: the widest range of pressures, high pressure must be selected, low equipment price, highest efficiency, small change of exhaust volume with exhaust pressure, and strong maintainability. Disadvantages: complex structure, many wearing parts, heavy maintenance work, general reliability, large size, vibration lots of movement and noise. Advantages of screw air compressors: strong reliability, easy operation and maintenance, good dynamic balance, low noise and vibration, large displacement, small size, and space saving. Disadvantages: After long-term operation, the screw gap becomes larger, the exhaust volume becomes smaller, and the maintainability is poor, regular maintenance costs are high.

The above are several basic methods for the selection of the sandblasting machine industry. In addition, it is better to find a professional engineer to check and calculate on the spot for special circumstances and needs.