There is an air compressor that has been out of service for a long time due to a fault in the power supply line. After replacing the line today, it cannot be started after power-on trial operation. Come and have a look~

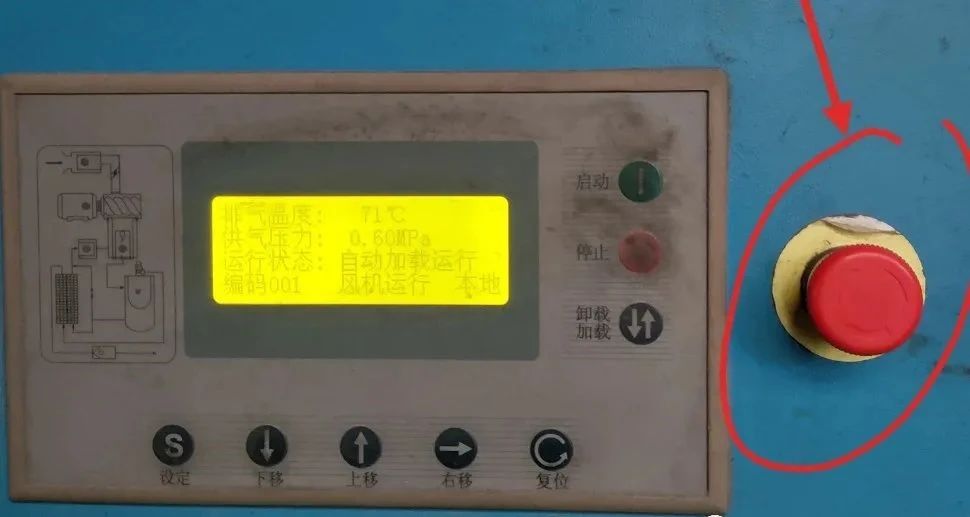

After the screw compressor is powered on, press the start button on the operation panel, and the LED on the panel will display the normal start-up procedure (Figure 1). According to the LED display, the air compressor should start normally at this time, but in fact it does not. All the contactors None of them sucked in.

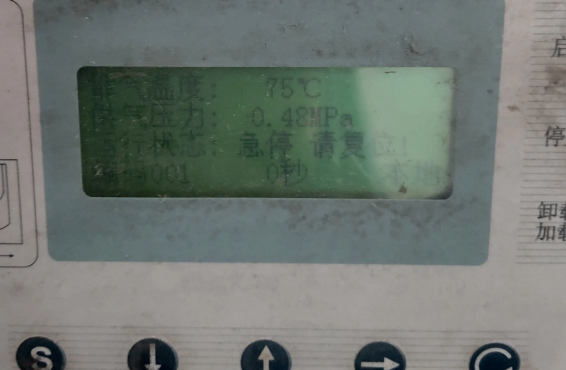

This kind of failure is actually easy to judge. Obviously, there is a problem with the common line of the control loop. Check the emergency stop button, press the emergency stop mushroom head, the LED displays "emergency stop, please reset" (Figure 2), release the emergency stop button and the "please reset" alarm disappears (there is a hole to be filled), and then find the emergency stop The buttons are bright and eye-catching, obviously replaced later. I asked the operator when he changed the emergency stop button, and the operator said he didn't know.

Then let's study this emergency stop button again. Because the air compressor has never been repaired before, and there is no electrical schematic diagram of it, under normal circumstances, the emergency stop button of the electromechanical equipment should be connected to the normally closed point of the control circuit, but the inspection found that there are two sets of lines behind the emergency stop button: One group is connected to normally open, and the other group is connected to normally closed.

I don't know exactly what logic defines the PLC to issue "emergency stop, please reset" on this machine, so I take it for granted that this alarm is connected to the normally open point-click the emergency stop button, and the normally open point is connected, PLC issued "emergency stop" alarm. The normally open point can be disconnected normally, and the normally closed point can be turned on normally, which means that the emergency stop button is fine.

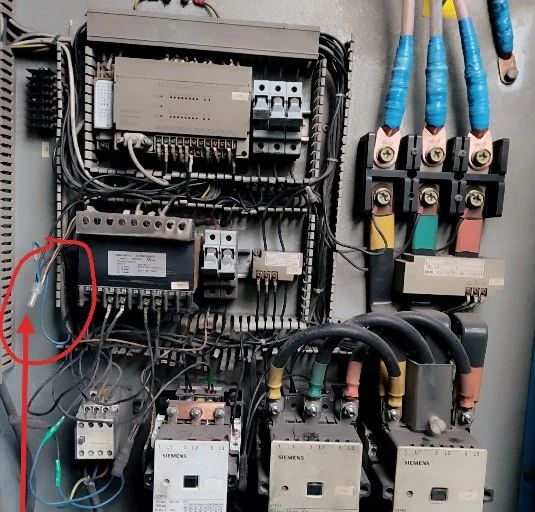

Then stroke the wires at the back, all the contactor coil voltages are 110V from the control transformer, and the control transformer 110V has two outlets, one enters the PLC terminal 32, and the other enters the insurance to go to the emergency stop button, because just now After checking the emergency stop button, there is no problem, so I squinted my eyes and did not use a multimeter to confirm.

All contactor coils have one end connected to the emergency stop (Figure 3), and the other end of the wire goes into the PLC terminals 27, 28, 29, and 31 respectively. There is no open circuit in the middle of all the lines, even if there is no drawing, you can see The action of the contactor depends on terminals 27, 28, 29, and 31, which are respectively connected to terminal 32.

At this time, the focus of my attention shifted to the PLC, thinking that the PLC might be damaged, causing all logic normally open points to fail to conduct. Send power again, press the start button on the control panel, observe the action of the PLC, the result is slapped again, the red lights of the corresponding output points of the PLC are successfully lit, and then measure the 110V voltage at terminals 27, 28, 29, and 31. It shows that there is no problem with the PLC, and things are back to the original point.

Think about it: the contactor coil is fine, the PLC is fine, the emergency stop button is fine, the connecting wire is fine, the auxiliary normally closed point of the contactor is fine, since there is no problem, why does the contactor not pull in?

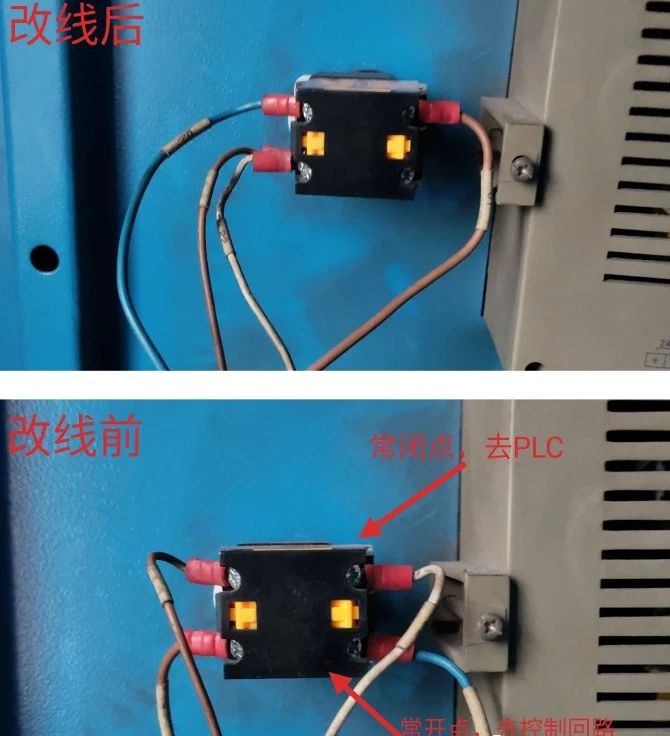

Etc., etc! Always close! Fuck me, a flash of inspiration suddenly appeared in my head. Could it be that the two sets of contacts of the emergency stop button are reversed? I jumped up from the ground and re-took the two sets of wires of the emergency stop button. Sure enough, the control transformer 110V went out, and the set of wires from the insurance to the emergency stop was connected to the normally open point of the emergency stop button! Laughing and crying, then change to the normally closed point, reverse the two sets of wires, change normally open to normally closed, and normally closed to normally open, but the problem comes again. After the modification, the LED screen on the panel will report an alarm of "emergency stop please reset" .

Obviously, the emergency stop button that was replaced later is different from the original emergency stop button. The original emergency stop button has two sets of normally closed, but the newly replaced one has one set of normally open and one set of normally closed. The buddy who changed the emergency stop button probably didn't notice the difference. Short the two wires to the PLC, the alarm disappears (Figure 4), press the start button, and the air compressor starts smoothly!

A problem caused by a simple emergency stop button wiring, I checked for a long time, and explained two points:

1. Believe in intuition (initial judgment is a problem with the common line of the control loop), but you cannot completely rely on intuition;

2. Check the wires carefully, don’t take it for granted, if you stroke the wire from the insurance to the emergency stop button at the beginning, the problem will be solved in a few minutes.

Expand knowledge:

How to reset the emergency stop of the screw air compressor? How to reset the emergency stop of the screw air compressor? The reasons for the emergency stop and reset of the screw air compressor are as follows:

1. Press the emergency stop switch. You can turn the emergency stop switch clockwise to see if it pops out. If it does not pop up, the emergency stop switch should be replaced.

2. The air compressor is idle for a long time. Please reset the emergency stop when the display is activated, but the reset does not work. It can be judged that the emergency stop switch is disconnected or the emergency stop control line is not in good contact. Replace or repair emergency stop switch.

The emergency stop button of the air compressor can only be used in emergency situations, and it is not recommended to use it in other situations.