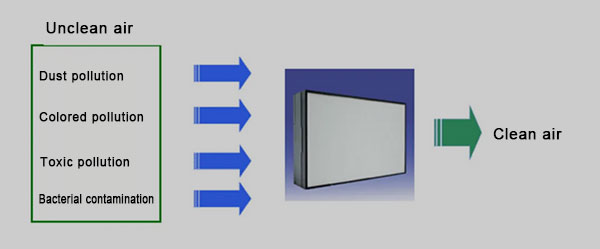

Air Filter refers to an air filtration device. Air filtration devices are generally used in clean workshops, laboratories and clean operating rooms.

The air compressor air filter (Air compressor filter) is composed of an air filter assembly and a filter element. The outside is connected to the air inlet valve

of the air compressor through joints and threaded pipes, thereby filtering dust, particles and other impurities entering the air. Different air compressor

models can choose the air filter to be installed according to the size of the air inlet volume.

The structure of air compressor air filter is different from that of other air filters, but the principle and material are similar.

Air filter material

The air filter materials currently widely used mainly include: Glass fiber filter paper, Polypropylene fibers, Polyester fiber filter material, Plant fiber filter material, Non-woven filter material, Activated carbon filter material.

Application scope of air filter

Electronic product manufacturing, Semiconductor, LCD and TP manufacturing, Biotechnology industry, Optical product manufacturing, Pharmaceutical manufacturing industry.

The principle of air filter

Dust particles in the air move inertly or irregularly with the air flow. When the moving air dust particles hit the filter media that can effectively intercept

the dust particles without causing excessive resistance to the air flow, the chaotically intertwined fibers of the filter media form. Countless barriers to

particles, the wide spaces between fibers allow airflow to pass smoothly.

The following is an introduction to the specific principles of the filter:

(For ease of explanation, assume that the dust is all spherical, and when in contact with the fibers inside the filter, it will stick to the fibers due to van der

Waals force)

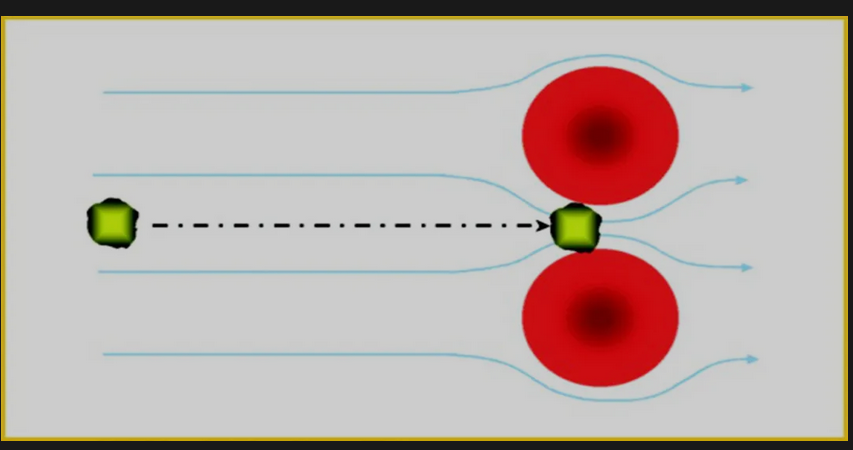

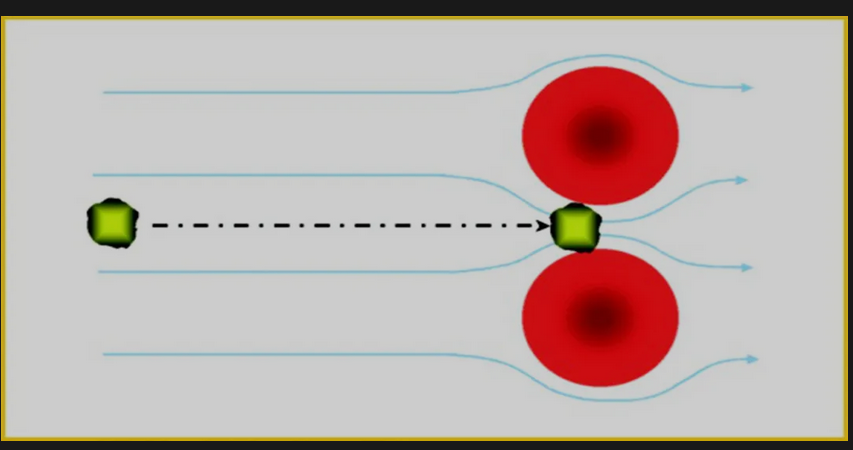

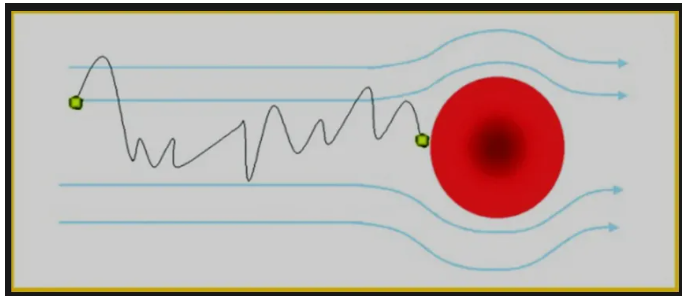

1. Inertia effect

Larger dust particles make inertial motion in the airflow, and the larger dust has no time to bypass due to inertia and directly hits the fiber. The higher

the airflow speed, the larger the dust particle size, the finer the fibers, the greater the number of fibers, and the greater the possibility of dust hitting

the fibers due to inertial force.

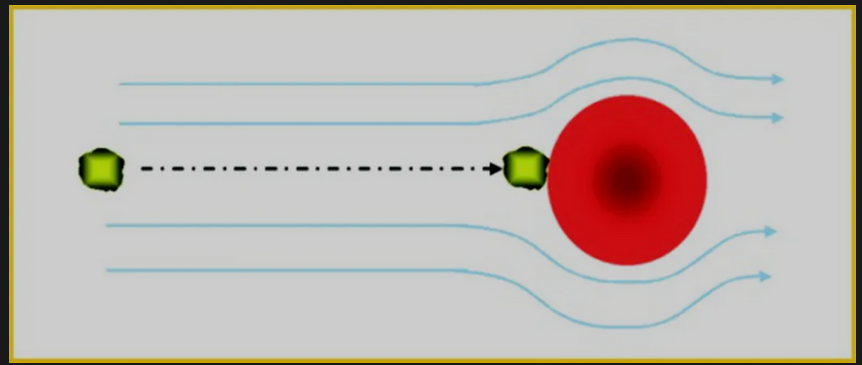

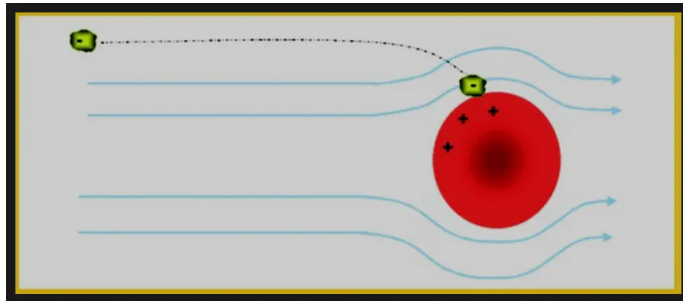

2. Interception effect

Small and light dust moves with the airflow. When the airflow rubs against the fiber surface, the dust is intercepted. The interception effect is independent of airflow velocity. The larger the dust particle size, the finer the fibers, the denser the fibers, and the stronger the interception effect. In order to obtain a good interception effect, the number of fibers in the filter material must be increased.

3. Diffusion effect

Dust smaller than 1um usually undergoes irregular diffusion motion due to the impact of air molecules, also known as "Brownian motion". If it hits the fibers it will be captured. The smaller the dust particle size, the finer the fiber, the smaller the airflow speed, the more intense the diffusion movement, and the more opportunities the dust has to hit the fiber.

4. Inertia effect

If the diameter of the dust is larger than the gap between the fibers, it will be blocked. For the air filter to have a good filtering effect on small dust particles, the filter material must contain a sufficient number of fine fibers.

5. Electrostatic effect

Filter fibers and airborne dust particles can become electrostatically charged for a variety of reasons, and dust particles are attracted to the fibers. Chemical fiber filters with very coarse fibers often have high initial efficiency due to their own static electricity, but in actual use, the filtration effect drops sharply.

As more and more dust is collected, the filtration efficiency of the filter layer also decreases and the resistance increases; when a certain resistance

value is reached or the efficiency drops to a certain value, the filter needs to be replaced in time to prevent Ensure high cleanliness requirements.