An oxygen booster is a mechanical device designed to increase the pressure of oxygen gas. It compresses the inhaled low-pressure oxygen through mechanical means (usually a piston or diaphragm), thereb

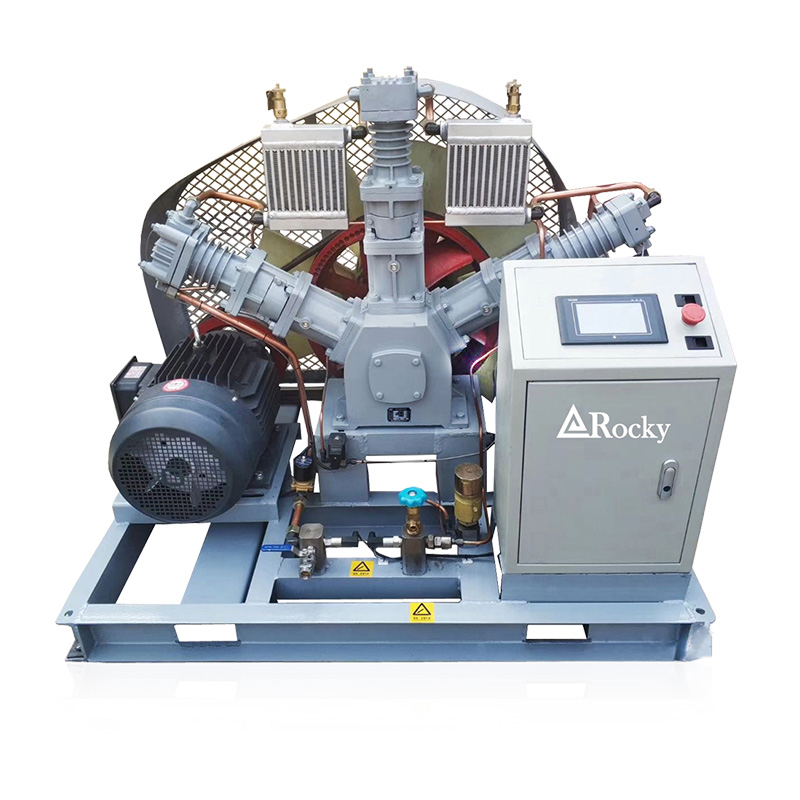

1. Extreme Safety (Oil-Free and Explosion-Proof Design)

• Absolutely Oil-Free: This is the most critical feature. The compression chamber (cylinder, piston, diaphragm, etc.) must be oil-free and lubricated.

• Anti-static and Explosion-Proof: All electrical components (such as motors, switches, and control cabinets) are explosion-proof to prevent sparks

from igniting oxygen. The machine is well grounded to eliminate the risk of static electricity accumulation.

2. Reliable Sealing

• High-grade sealing technology and materials ensure zero leakage of oxygen under high pressure. Leakage not only wastes gas and reduces purity,

but also creates an oxygen-rich environment at the leak point, greatly increasing the risk of fire.

3. Effective Cooling System

• Gas generates a significant amount of heat when compressed. In high-pressure oxygen, overheating is extremely dangerous.

• Oxygen boosters are typically equipped with efficient air or water cooling systems to ensure that the outlet oxygen temperature remains within a safe

range, protecting the equipment and downstream components.

4. Extremely High Cleanliness Requirements

• Before leaving the factory, all oxygen channels must undergo rigorous degreasing, cleaning, and purification to thoroughly remove any grease, particulate

matter, and contaminants. Assembly must also be performed in a clean environment.

5. High and Stable Output Pressure

• Multi-stage boosting is typically used, achieving very high output pressures (up to 30 MPa or even higher) through progressive compression. Precision

pressure regulating valves are also used to ensure stable output pressure to meet precise application requirements.

6. Automated Control and Safety Protection

• Modern oxygen boosters are typically equipped with an intelligent control system (PLC) and multiple safety protection devices.

For technical support or inquiries, please leave your contact information.