The compression process of the oil-free scroll is realized by the rotating motion of the fixed scroll and the movable scroll. Air enters from the outside of the main engine, and the moving scroll clos

Compared with the traditional compressor, the oil-free scrolltype has excellent performance such as novel structurecompact size, light weight, low noise level, long life and lowmaintenance cost.lt is known as "maintenance-free aircompressor" and is an ideal model for air compressorsbelow 50HP.

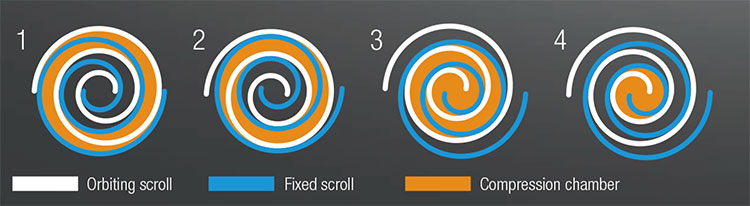

Scroll Compression Principle

As the orbiting scroll goes from No, 1 to No.4 position, the room of the symmetrical crescent-shaped compression chambers isaradually reduced. compressing the air contained within, This is then discharged through the central exhaust port.

Oil-free Scroll air compressor Advantages

Fully Oil-free

Class 0 oil-free is certified by GermanTUV organization.

Low Vibration

The high-pressure area aroundthe axis is evenly distributedwithout eccentricity, good balanceand well controlled vibration.

Super Silent

Reasonable vibration and noisereduction design, smooth outputairflow without fluctuation, lownoise and low vibration.

Intelligent and Reliable

Multi-stage scroll air-ends,automatically controls the scrollunits according to the air demand.Failed air-end doesn't affect to thesystem as all units are controlledindependently.

Application industry

Oil-free scroll screw air compressors are used in food (wine, beverage and other food processing plants), medical treatment (clinics, hospitals, gas supply, pharmaceutical processing, etc.), new energy vehicles (braking system, air conditioning system), oxygen tanks , laboratory, printing, chemical industry, precision drawing and coating and other fields.

For technical support or inquiries, please leave your contact information.